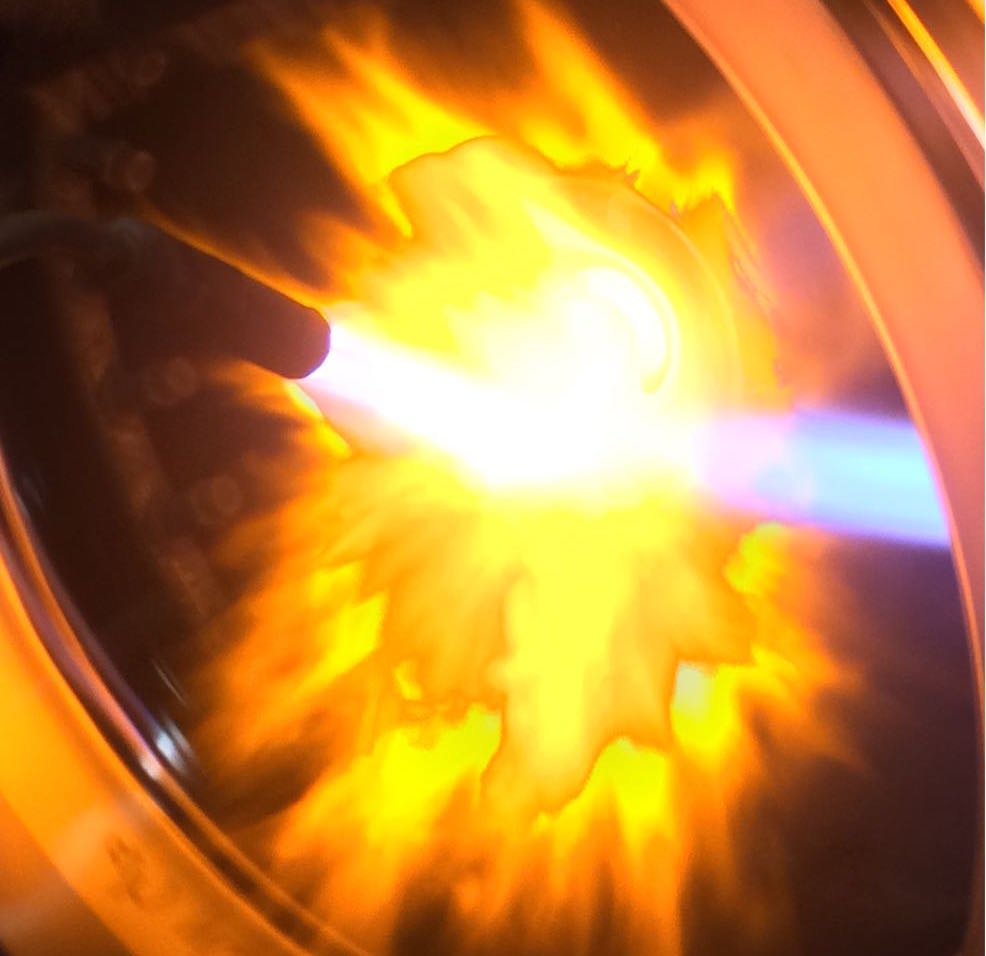

Blow Glass Technology S.R.L. is born from the collaboration with a consolidated factory which works in the borosilicate 3.3 glass second processing, also known as Pyrex.

The factory works mainly on glass applications for chemical, pharmaceutical, industrial, scientific and for laboratory uses and also for artistic uses in particular cases.

We are a dynamic and growing factory with a 20-years experience in this field thanks to expert collaborators.

Bl. Glass produces highly competitive products from an economic, technical and constructive point of view, the final product is tested, controlled and without internal strains, processed with special programmable ovens.

We can produce any piece, from the list, from a design or a special piece based on the customer request.

We will be glad to fulfill every request as soon as we can.

Blown Glass Technology

REPAIRS AND ESTIMATE IN 24 HOURS!

Blown Glass Technology has a special line dedicated to urgent repairs that need to be made in 24h, where a prompt operation is necessary so as not to incur in the wasting of the active principle in process.

+39 3357060904

WhatsApp contact

Prodotti

In process products list

Blown Glass Technology is committed on the field in an accurate design and a direct collaboration with the costumer in order to have highly performing products from the technical point of view, reliable and safe, thanks to industrial outstretching ovens, polarimeters, diamond grindings and frosting for holding the vacuum with precision equipment.

- Da DN15 a DN450

- Curve

- Tee

- Colonne a riempimento

- Da DN50 a DN450

- Calotte laboratorio

Da DN60 a DN200

- Reattori incamiciati tripla camicia

- Reattori da un minimo di 1lt a un max di 100lt

- Reattori incamiciati da un minimo di 1lt a un max di 100lt

- Refrigeranti a serpentina da DN40 a DN450

- Valvole da DN15 a DN80

- Teste di reflusso da DN40 a DN300

- Separatori di fase

Video

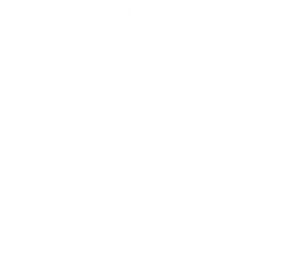

Linear welding DN300

All weldings are made with the highest precision, maintaining uniform thicknesses on the whole surface, in ordert to guarantee the structural integrity of the product.